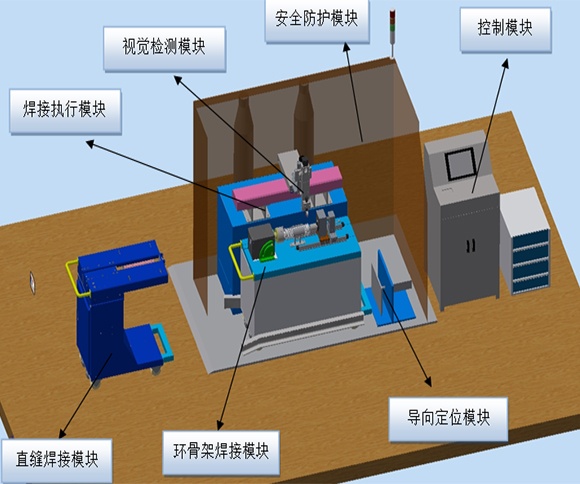

Filter frame straight seam welding and small hole plug welding robot cell

Filter frame straight seam welding and small hole plug welding robot cell includes welding detection module, visual detection module, control module, guide positioning module, straight seam welding module, ring frame welding module, safety protection module, etc. It has been fully considered in terms of accuracy, production rhythm, safety, reliability and stability. It greatly reduces the requirements for workers' professional welding quality, ensures the stability of welding quality, and greatly improves welding efficiency.

Application:

This welding robot cell is widely used in water treatment, air purification, automobile manufacturing, petrochemical, medical, filtration equipment, industrial equipment manufacturing and other industries.